We support you from the concept study to the process engineering detail planning, modular as well as holistic. An integrated digital chain of planning tools in combination with a well-rehearsed team and proven interfaces to the other plant planning trades reduces the planning effort and lays the foundation for efficient operation and maintenance processes. We use digitized networked tools from the first

Would you like to get to know ISG Engineering Head Dr. Mickael Planasch and his team of experts? Then watch our video (in German) on Youtube!

You can find our brochure "Future-proof plant planning and erection" here.

We convert existing plant documentation into digital form and make these efficiently accessible for the latest planning tools. In addition, we use automated tools to create a digital 3-D model of the analyzed area.

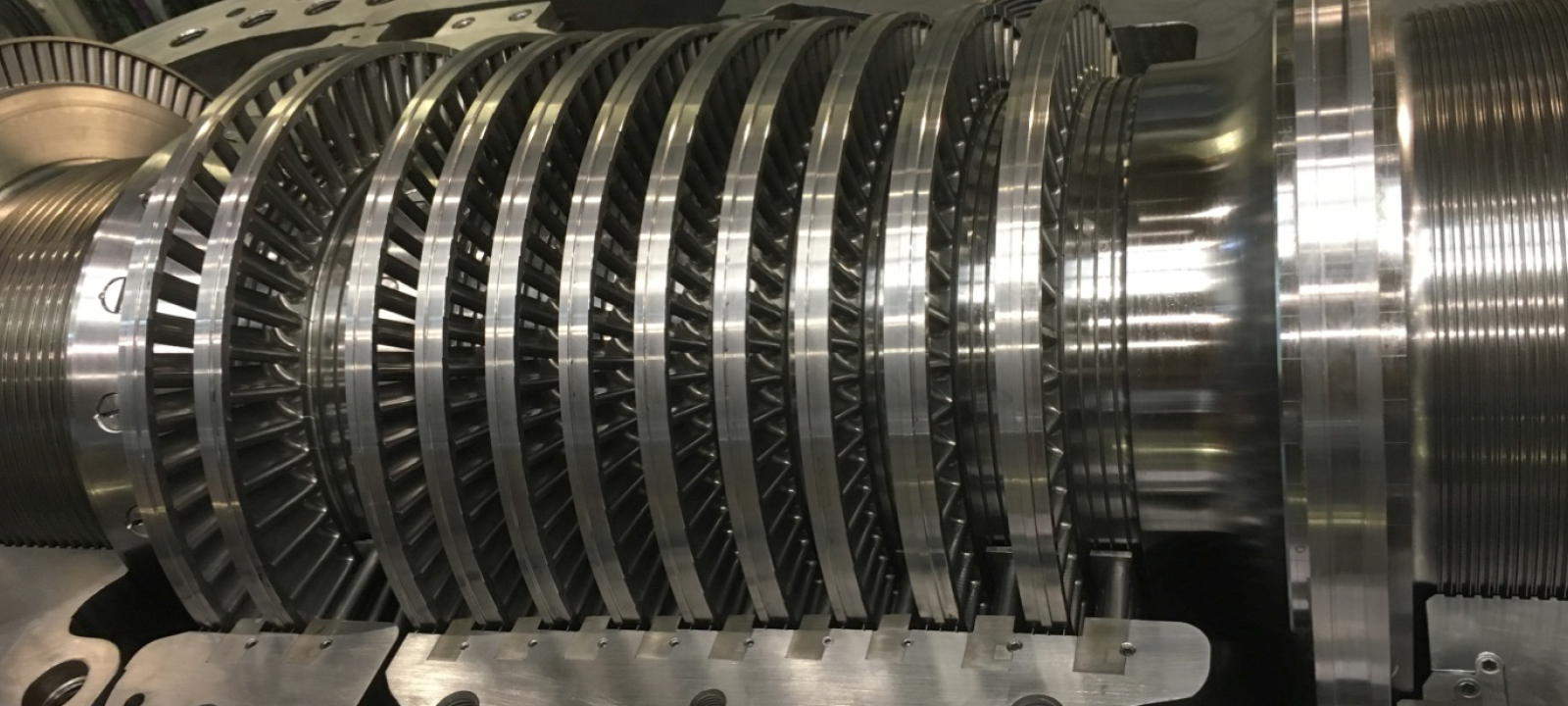

Our experts for process and plant engineering develop profitable and future-proof plant concepts specifically matched to your production processes. With the assistance of the latest tools under the GENDORF CAX 4.0 concept, we develop plant concepts down to the details for implementation maturity.

Our employees specify the required components and take care of defining all required parameters to specify a plant component or an apparatus, pursuant to the functional requirements.

Our subject-matter experts specify your pipe assemblies and 3-D layout planning documentation based on functional requirements Our sophisticated planning tools give you on demand insight into the project – with the assistance of terminal server applications.

Our specialists perform strength calculations and conduct functional simulations of process engineering unit operations or plant concepts.

Mit einer traditionellen Weihnachtsspende unterstützt InfraServ Gendorf (ISG) gemeinnützige Projekte in der Region. Die Spenden kommen unmittelbar der Arbeit für Menschen in besonderen Lebenslagen zugute – von frühzeitiger Präventionsarbeit bis hin zur Erfüllung letzter Wünsche schwer erkrankter Menschen.

Die Zusammenarbeit von Standortbetreiber InfraServ Gendorf und des Mobilitätsanbieters goFLUX Mobility wurde beim Bundeswettbewerb „Arbeitswege gestalten. Mobil in ländlichen Räumen“ ausgezeichnet.